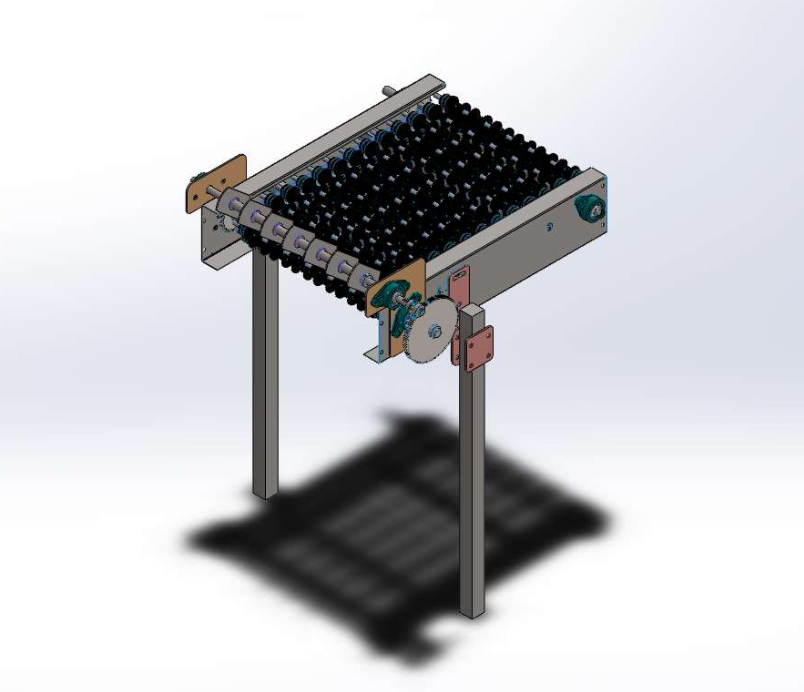

Precision Product Aligner

Automated alignment system for efficient downstream processing.

The Product Aligner was designed to streamline the initial stages of the production line by positioning products accurately for downstream processing. This system serves as the foundation for an efficient and fully automated production workflow.

Key Contributions

- High-Precision Alignment:

- Developed a high-speed alignment system using servo motor control to ensure consistent precision.

- Optimized the system for seamless integration with sorting and downstream automation systems.

- Machine Learning Integration:

- Applied object detection models to adapt alignment dynamically based on product size and shape.

- Implemented real-time feedback loops to minimize alignment errors and improve accuracy.

Impact

- Eliminated bottlenecks in the production workflow, enabling a smooth transition to fully automated processes.

- Contributed significantly to scaling production capacity from 2.5 tons to 17 tons daily.

Automated product aligner integrating AI and precision control for efficient placement.