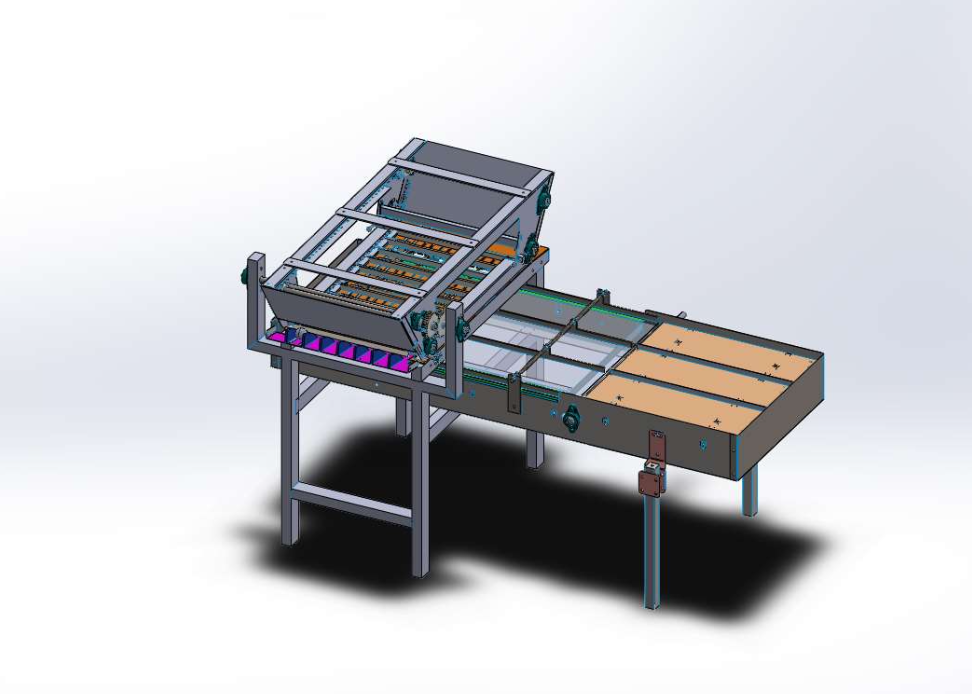

Dual Sorting Systems for Size and Integrity

Automated sorting powered by AI and automation for size and quality differentiation.

To meet diverse market demands, I designed two automated sorting systems: one for size-based categorization and another for quality differentiation, both optimized using AI-driven automation.

Key Contributions

- Size-Based Sorting:

- Developed an automated system to classify products into large and small categories using sensor-based technology.

- Integrated predictive models to dynamically adjust sorting thresholds based on real-time production requirements.

- Integrity-Based Sorting:

- Deployed computer vision models to detect structural anomalies, ensuring efficient separation of cracked and uncracked items.

- Automated downstream packaging processes by linking sorting outcomes to the packaging system.

Impact

- Boosted the production line’s efficiency and scalability from 2.5 tons to 17 tons daily.

- Enabled diversified packaging strategies for different market segments, including export-quality products.

- Demonstrated the effective application of AI and automation in high-volume manufacturing.

Dual sorting systems powered by AI for size and quality differentiation.