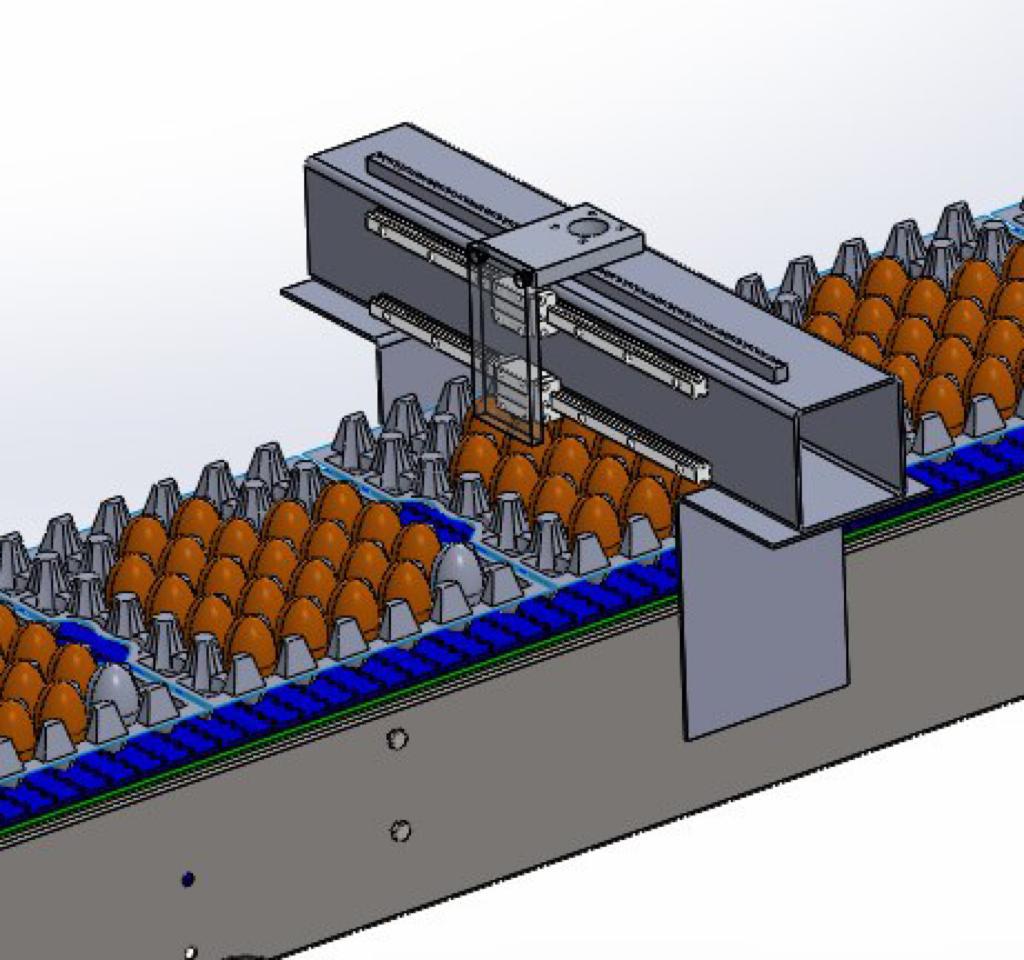

Automated Product Printing System

Intelligent system for expiration and production date marking in manufacturing.

As part of the production line overhaul, I developed an automated product printing system that uses intelligent control to ensure precise marking of expiration and production dates. This system is a vital component of the manufacturing workflow by enabling high-speed, reliable, and traceable operations.

Key Contributions

- Intelligent Control:

- Designed a mechanism to synchronize with the conveyor system for real-time printing.

- Integrated control algorithms to detect and correct errors during production.

- Machine Learning Application:

- Utilized optical character recognition (OCR) to verify print quality and minimize errors.

- Improved predictive maintenance by analyzing machine logs to anticipate potential issues.

Impact

- Eliminated manual errors, ensuring 100% compliance with regulatory standards.

- Supported the 17-ton daily production output by automating a critical stage of the workflow.

- Enabled seamless international shipping by meeting global traceability standards.

High-precision automated product printing integrated with intelligent control and machine learning.